Food safety standards are a crucial factor in the food industry. It is a top priority to ensure that the products produced are safe for public consumption.

Issues such as bacterial contamination and harmful chemicals pose challenges in this industry. Therefore, we are here to help address these challenges through the appropriate chemicals for clean-in-place (CIP) and clean-out-of-place (COP) processes, equipment cleanliness and sanitation, and providing halal-certified and food-grade lubricants.

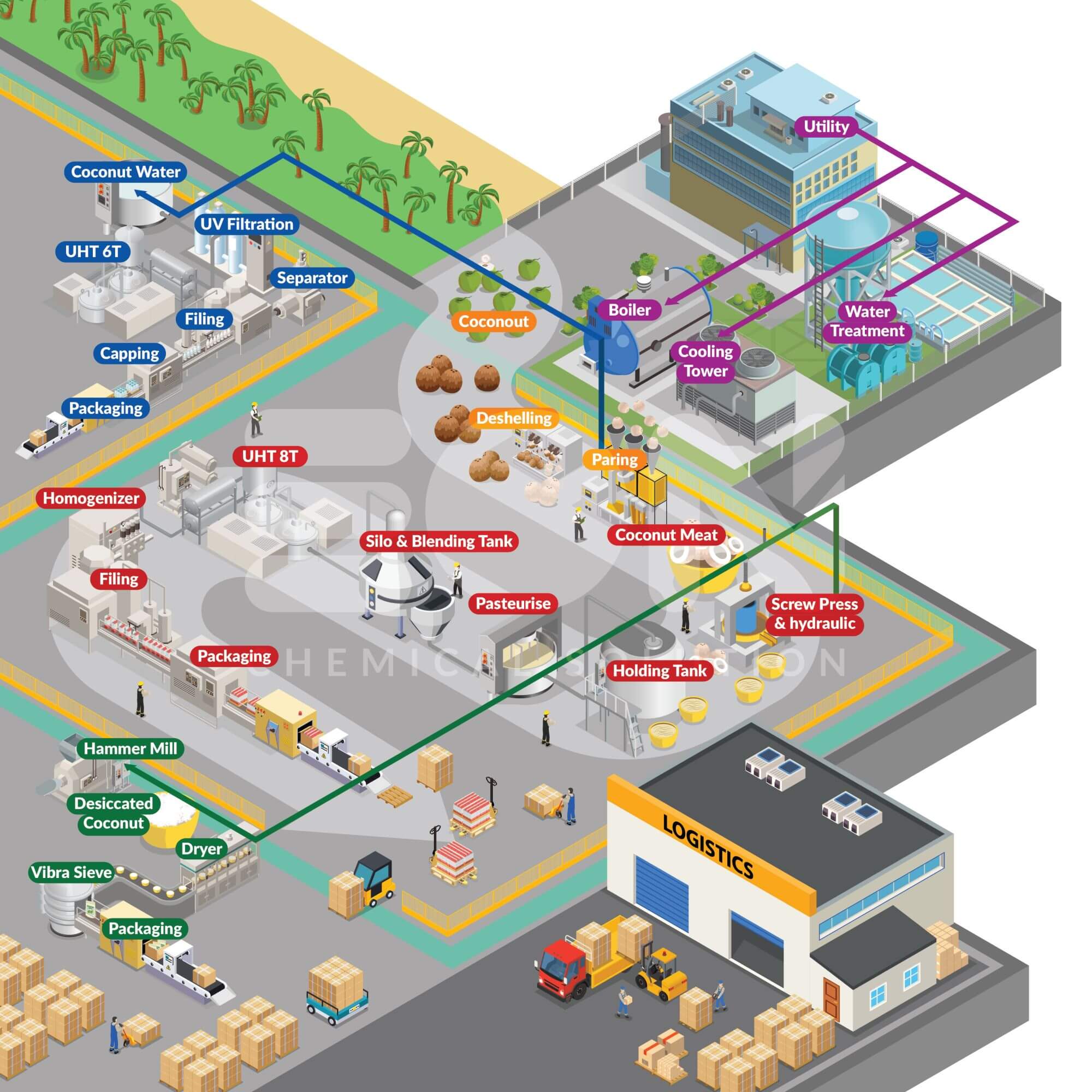

Food Industry Process Illustration

Tips: Use two fingers to zoom in on the image

Food Industry Problem and Solutions Table

Click the link in the “Equipment” column to see the details.

| No | Equipment | Problem | Solution |

|---|---|---|---|

| 1 | Pairing & Deshelling | Coconut Water | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| 2 | UHT 6T | Coconut Water | Regreasing Interval Too Short | LE Lubricant |

| Long CIP Cycle Time | Eon CIP | ||

| Microbiological Contamination | Eon Sanitizing | ||

| 3 | Separator | Coconut Water | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Machine Cleaning Time | Eon COP | ||

| 4 | Filling | Coconut Water | Long CIP Cycle Time | Eon CIP |

| Microbiological Contamination | Eon Sanitizing | ||

| Bottle Contains Contaminants | Eon WashBrite | ||

| Stains/scale on equipment | Eon Bright | ||

| Regreasing Interval Too Short | LE Lubricant | ||

| Grease/Oil on the Chain Contaminates the Product | Molykote AFC | ||

| Bottles Fall While on the Conveyor | Eon DryLube | ||

| 5 | Capping & Packaging | Coconut Water | Printing Machines/Parts Contaminated with Ink | Eon Rollink |

| Dirt from Glue on Labeling Machines | EonSolv | ||

| Grease/Oil on the Chain Contaminates the Product | Molykote AFC | ||

| Regreasing Interval Too Short | LE Lubricant | ||

| 6 | Screw Press & Hydraulic | Coconut Milk | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Changing Oil Too Often | LE Oil | ||

| 7 | Holding Tank | Coconut Milk | Product residue is difficult to clean | Eon COP |

| Microbiological Contamination | Eon Sanitizing | ||

| 8 | Pasteurize | Coconut Milk | Unstable Steam | Eon Boiler Chemicals |

| Mineral and Product Residues Are Difficult to Clean | Eon CIP | ||

| 9 | Silo & Blending Tank | Coconut Milk | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Product residue is difficult to clean | Eon COP | ||

| 10 | UHT 6T | Coconut Milk | Regreasing Interval Too Short | LE Lubricant |

| Long CIP Cycle Time | Eon CIP | ||

| Microbiological Contamination | Eon Sanitizing | ||

| 11 | Homogenizer | Coconut Milk | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Cleaning the Machine Takes a Long Time | Eon COP | ||

| 12 | Filling | Coconut Milk | Long CIP Cycle Time | Eon CIP |

| Microbiological Contamination | Eon Sanitizing | ||

| Bottle Contains Contaminants | Eon WashBrite | ||

| Stains/scale on equipment | Eon Bright | ||

| Regreasing Interval Too Short | LE Lubricant | ||

| Grease/Oil on the Chain Contaminates the Product | Molykote AFC | ||

| Bottles Fall While on the Conveyor | Eon DryLube | ||

| 13 | Packaging | Coconut Milk | Printing Machines/Parts Contaminated with Ink | Eon Rollink |

| Dirt from Glue on Labeling Machines | EonSolv | ||

| Grease/Oil on the Chain Contaminates the Product | Molykote AFC | ||

| Regreasing Interval Too Short | LE Lubricant | ||

| 14 | Hammer Mill | Desiccated Coconut | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Product residue is difficult to clean | Eon COP | ||

| Microbiological Contamination | Eon Sanitizing | ||

| 15 | Dryer | Desiccated Coconut | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Changing Oil Too Often | LE Oil | ||

| 16 | Vibra Sieve | Desiccated Coconut | Grease easily hardens/melts, change bearings frequently | LE Lubricant |

| Product residue is difficult to clean | Eon COP | ||

| 17 | Packaging | Desiccated Coconut | Printing Machines/Parts Contaminated with Ink | Eon Rollink |

| Dirt from Glue on Labeling Machines | EonSolv | ||

| Grease/Oil on the Chain Contaminates the Product | Molykote AFCSeries | ||

| Regreasing Interval Too Short | LE Lubricant |

Home

Home